In today's conditions, the management of product data has become one of the biggest requirements in order to offer qualified products to the market. To meet this requirements, our primary goal is to ensure that the functional and physical characteristics of the product are defined, documented, recorded, transferred to the relevant documents, data and product, and to continue this methodology throughout the life cycle of the product. Bringing people, data, and processes together and create a common language to be followed and managed in the digital environment, from the idea stage to the end user. Providing support throughout the lifecycle of the product, which guarantees the functional and physical characteristics of the product, and the transfer of changes to the relevant documents. It will help you to reduce corrective action costs and will boost efficiency. We can assist you to achieve your goals by building data management system which includes all the stages of product development phases (Concept, design, produce, maintain, decommision) by following world-recognised CM2 rules. Staying competitive needs that your product portfolio and new product presentation processes align with your strategic sustainability and growth objectives. Placing quality at core of its reproduction process, GES, which successfully offers reverse engineering solutions, produces distinct products, which are modeled and improved by transferring them to a digital medium after an effective information extraction and analysis process. In addition to its design and production capabilities, GÜNSEL Engineering Solutions offers paint applications, which is a complementary work, to its business partners with high quality and unlimited colour options. In the works where modern paint equipment are used by expert technicians, long-lasting results with high quality standards are achieved in the most sustainable way. Welding works, which are actively used in different stages such as prototyping, pre-production and mass production, are carried out on the basis of high accuracy with skilled technicians, modern machines and benches within GES. In this context, high quality standards are embraced in manufacturing the end products with the effective use of high-precision machines and tools, which are also used in the defence industry. Equipped with all electric injection Krauss Maffei machinery, one of the leading brands in its field, for needs in different sizes, GÜNSEL Engineering Solutions along with its trained operators offers its business partners the opportunity to produce at high quality standards. Thermoforming applications within the body of GES, where different production methods are successfully applied, are employed in production with unlimited shaping options, different material preferences and high production capabilities thanks to the mold design and manufacturing GÜNSEL Engineering Solutions employs a team of highly skilled, quality-oriented technicians and operators who are experts in their fields in the production line created with modern machines for innovative solutions. Our lines, which produce value-added products based on the zero-defect product principle, successfully apply high quality standards in different fields.

Low voltage, High voltage, Battery box wire harness

Harness

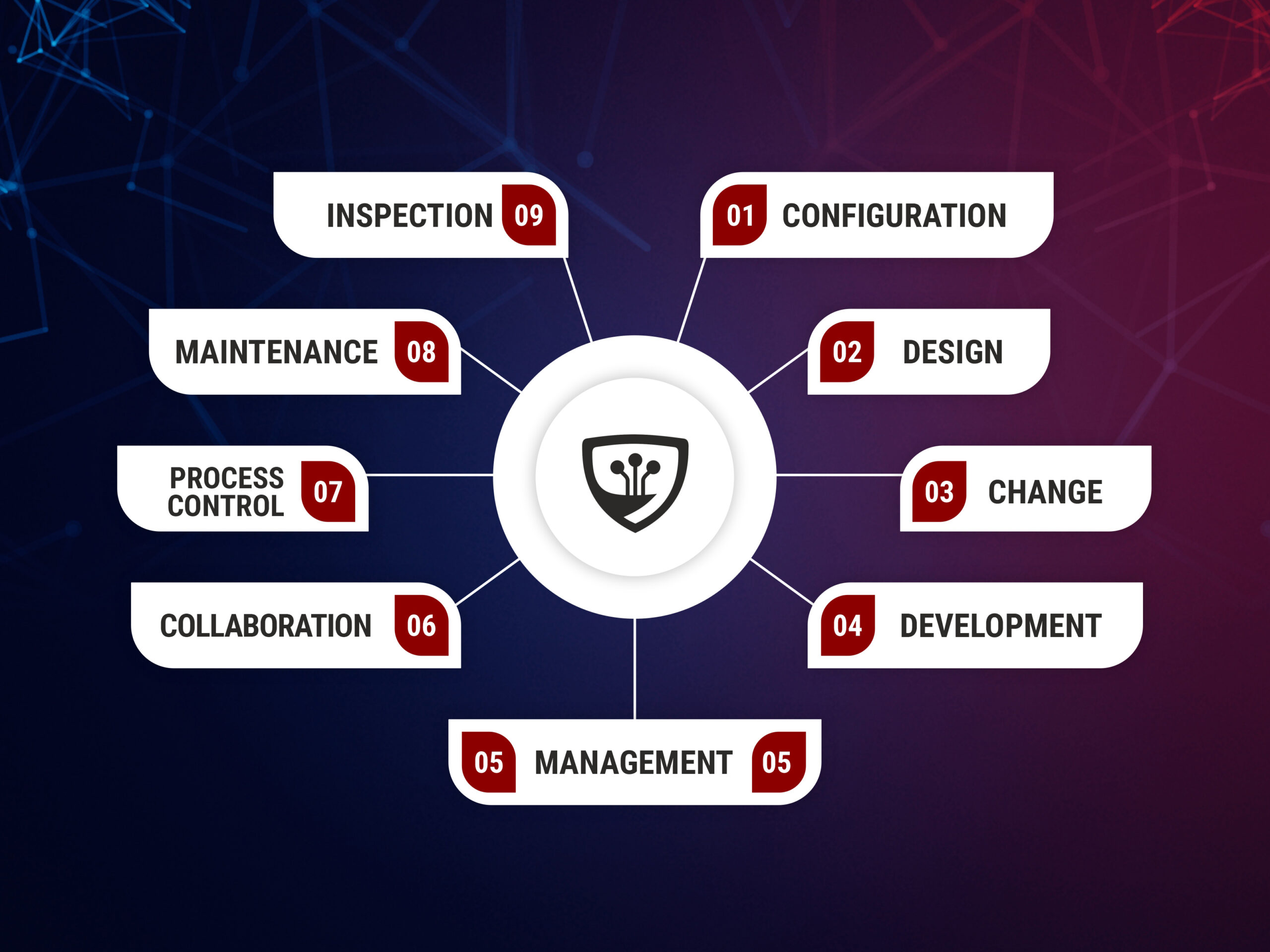

PLM Solutions

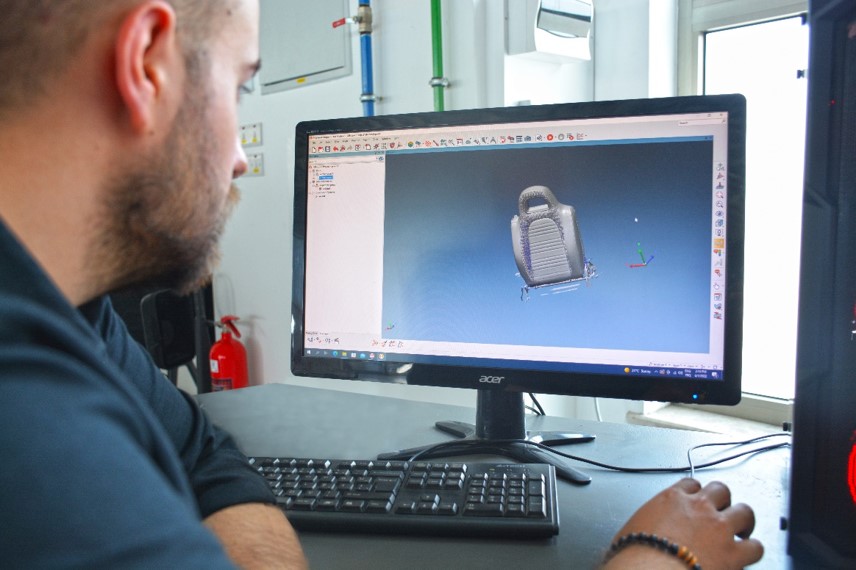

Reverse Engineering Solutions

Paint Applications

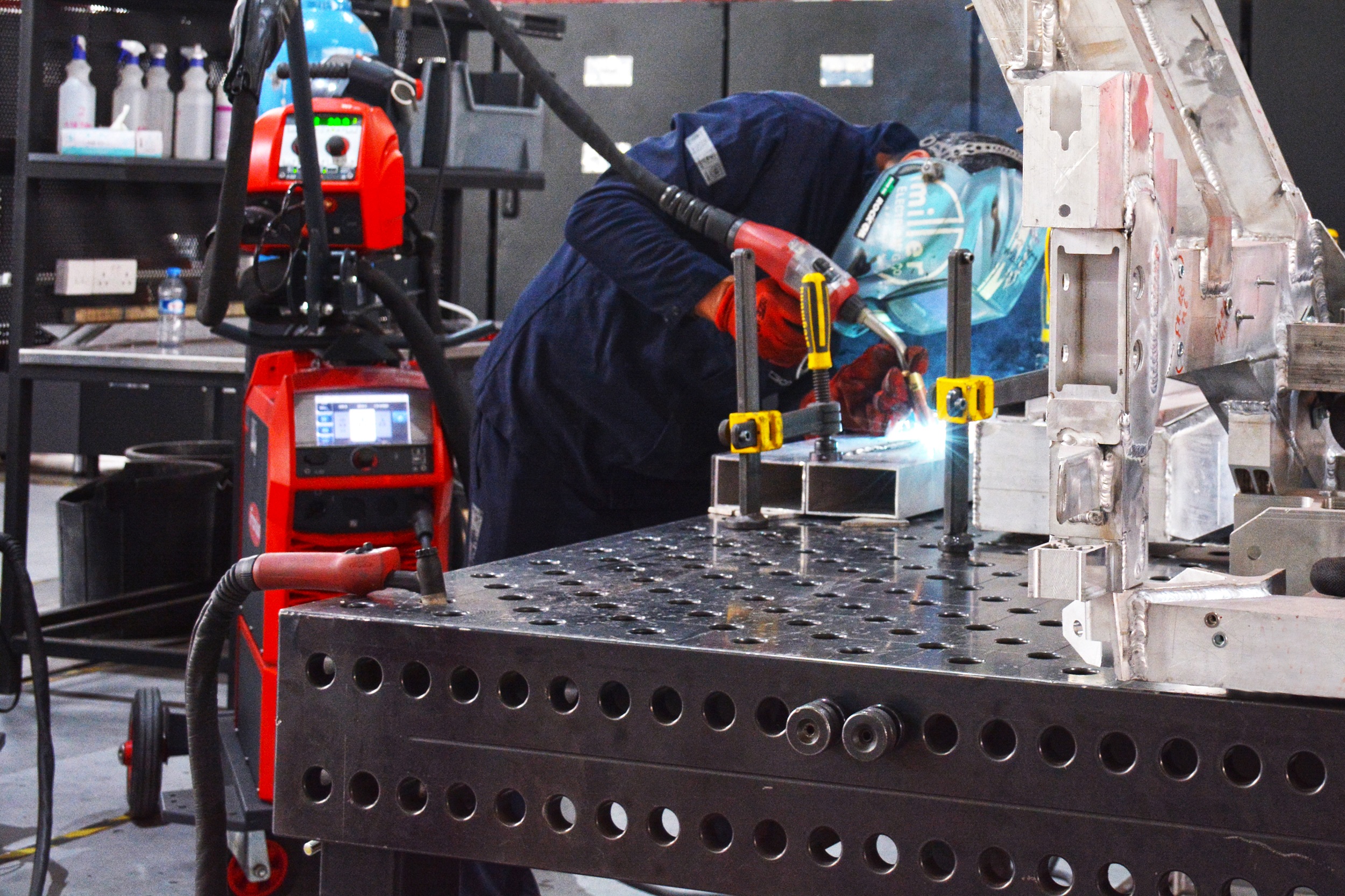

Welding Applications

Injection Applications

Thermoforming Applications

Machine Manufacturing Capabilities